Calculating Labor

This guide explains how to calculate and apply crew labor within Sections of a proposal. The labor calculation feature is grounded in real-world experience and designed to help contractors bid accurately, build realistic schedules, and consistently meet profitability goals.

Why Labor Calculation Matters

The labor calculation system was developed from field-tested time studies over the last 20 years. For example, a two-person crew using a skid steer was once tasked with moving 100 yards of topsoil from the street to a backyard. By measuring bucket volume, timing each cycle, and accounting for corrections and cleanup, the installation time was determined to be 8 minutes per yard for rough grading. Final grading for sod or seed is calculated separately.

This approach was later applied to other materials such as bark, boulders, rock, and sprinklers. The key mindset shift is to begin thinking in minutes, not just days or hours. The goal is not to bid cheaply, but to bid accurately. Accurate labor estimates allow crews to hit schedule targets, maintain motivation, and protect profit margins.

A common misconception is that labor estimates are only useful for low-cost bidding. In reality, they are essential for achieving your Profit Genie goals. Overages in overhead, materials, or labor directly reduce profitability. While overhead and materials can be controlled through realistic budgeting and job-specific totals, labor is the most likely to exceed estimates.

Even a one-day labor overage can result in both additional crew costs and delayed job starts, which compounds the loss. For example, if a two-person crew generates $1,000 in PMM (Production Minus Materials) per day, a one day delay results in both the loss of that $1,000 and the extra labor expense. Conversely, finishing a job one day early creates a $2,000 swing in your favor, $1,000 saved for finishing early and $1,000 earned for starting the next job a day early.

The Myth: “Every Job is Different”

Labor Entry Scenarios

Scenario 1: Known Minutes Per Unit

If the crew time it takes to install a unit of the material is already known, labor can be entered directly:

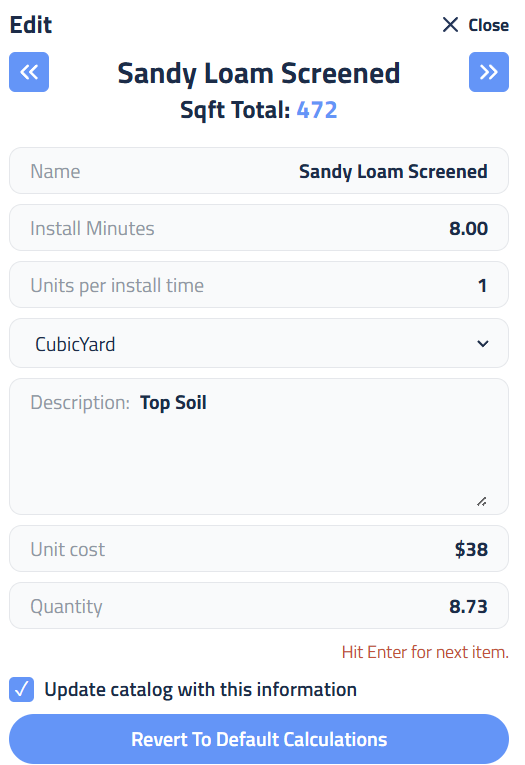

- Click the Edit icon next to the material (e.g., Sandy Loam Screened).

- Enter 8 in the Install Minutes field.

- Enter 1 in the Units per Install Time field.

- Check “Update catalog with this information.” If you want to save this time for other proposals as well.

Elevation Advisor will calculate total crew hours by multiplying the Quantity by the Install Minutes.

Scenario 2: Known Total Crew Hours

If the exact install minutes per unit are unknown but total crew hours needed to install that material are known:

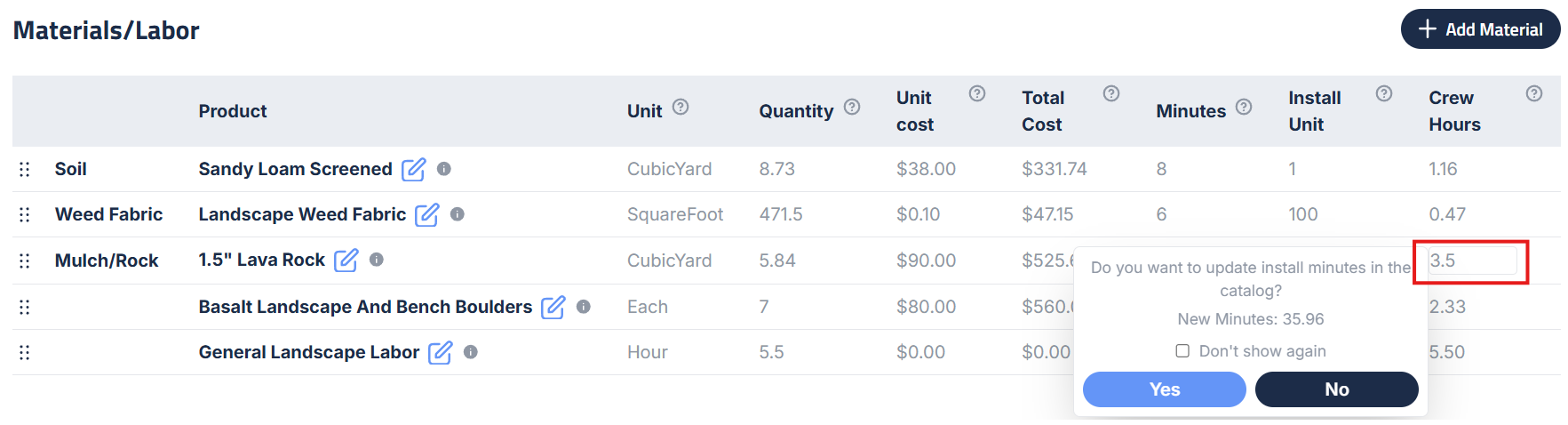

- Double-click the Crew Hours field (e.g., 1.5” Lava Rock)

- Enter the total crew hours required to install 5.84 cubic yards of rock (e.g., 3.5).

- Elevation Advisor will reverse-engineer the install rate (e.g., 35.96 minutes per cubic yard).

- Choose Yes, to update the catalog (you want to use this time for other projects) or No, if project-specific.

Scenario 3: Small-Unit Materials

For materials measured in small units, it’s not practical to think in fractions of a minute so just scale the Units per Install Time up:

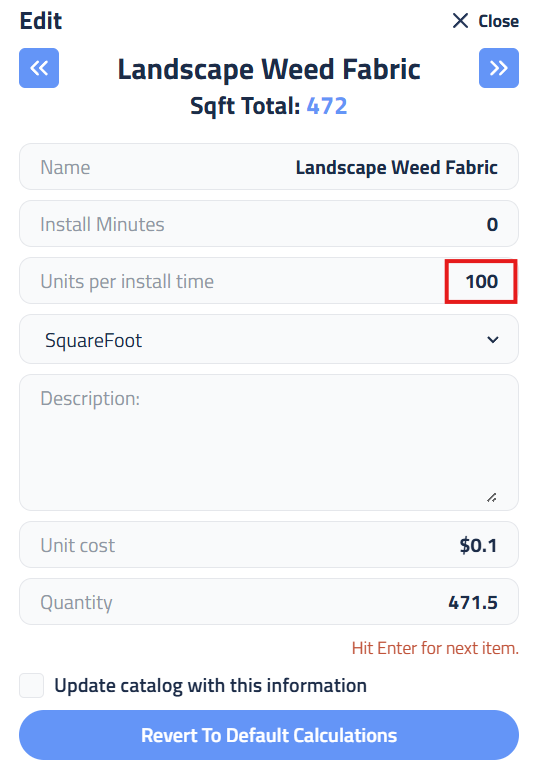

- Click the edit button next to the material you are working with (e.g., Weed Fabric).

- Change Units per Install Time to a practical scale (e.g., 100 square feet).

- Leave Install Minutes at 0 and Save.

- Now just like you did in scenario 2 double click Crew Hours and enter how many hours will take to install (e.g., 0.42 hours for 41.5 square feet).

- Elevation Advisor calculates install minutes per 100 square feet. In this case, 5.34 minutes.

Scenario 4: General Labor Line

For complex installs where labor is not tied to individual materials:

- Click Add Material.

- Search for your labor item such as **General Landscape Labor **

- Select Add New Material.

- Name it General Landscape Labor.

- Add how many Crew Hours you want to include in the Quantity and Save

This method is useful for transitioning from other systems or for quick lump-sum labor input.

Scenario 5: Variable Labor Times for the Same Material

When the same material has different install times based on usage:

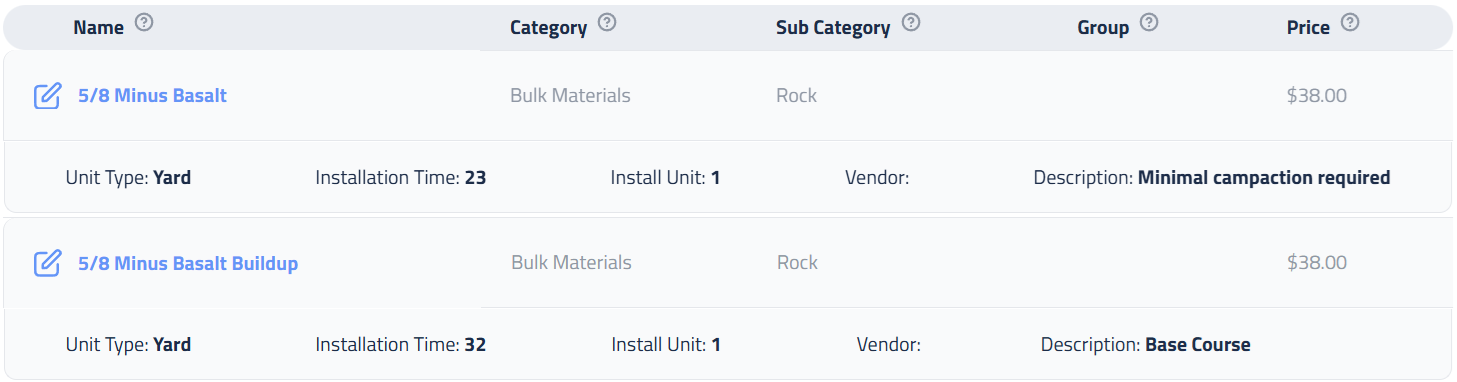

- Create duplicate catalog entries with distinct names.

- 5/8" Minus Basalt - light compaction: 23 minutes per cubic yard

- 5/8" Minus Basalt Buildup - Heavy compaction: 32 minutes per cubic yard

This ensures bids and schedules reflect actual labor requirements.

If a crew reports updated install times mid-job:

- Open the product catalog.

- Search for the material.

- Edit the Install Time field.

- Save the updated time.

This ensures future proposals use the most accurate labor data.

When to Skip Per-Material Labor

Not all items require individual labor entries. For systems like irrigation, labor is typically assigned to major operations:

- Trenching

- Pipe installation

- Sprinkler head setup

Smaller components are bundled into these operations to maintain accuracy without overcomplicating the workflow.

Updated on: 01/28/2026

Thank you!